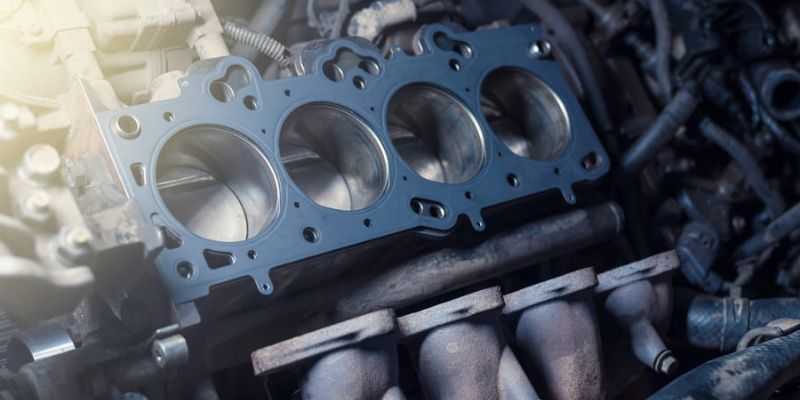

A cylinder head is a major element in an internal combustion machine, deposited at the top of the machine block. It covers the machine’s cylinders, containing essential corridors like the input and exhaust faucets, spark entrapments, and energy injectors. The head seals off the combustion chamber and allows air, energy, and exhaust gases to flow into and out of the cylinder head reconditioning head. Usually composed of accouterments like aluminum or cast iron, this cylinder head has to resist the blisteringly high temperatures and pressures generated during combustion. It is key to machine efficiency, effectiveness, and longevity.

Part of the Combustion Process

The cylinder head plays a main part in the combustion process. Inside it, the input and exhaust faucets regulate the inflow of gases into and out of the cylinders. During the input stroke, the input stopcock opens to let in the air-energy admixture, and the exhaust stopcock opens to expel exhaust gases during the exhaust stroke. The camshaft within the cylinder head controls the precise timing of these stopcock openings and conclusions. The cylinder head also holds the spark entrapments that enkindle the air-energy admixture, initiating combustion to produce power in the machine.

Cooling System Management

An equally significant role of the cylinder head is regulating machine cooling. It features coolant passages that coolant can pass through to help dissipate combustion heat. You don’t want the machine to heat, and the cylinder head sends the coolant around the combustion chamber and critical parts (the intake) to avoid that. Overheating can beget severe damage to machine factors, and the cylinder head’s cooling system helps this. Proper heat operation contributes to machine effectiveness and prevents expensive repairs by maintaining a stable operating temperature.

Air-Energy Admixture Control

The cylinder head is also responsible for controlling the air-energy admixture entering the combustion chamber. The input manifold is connected to the cylinder head, where the air-energy admixture is directed into the cylinders. Ultramodern cylinder heads frequently feature integrated energy injectors that precisely control the quantum of energy fitted into the air input. The precise admixture of air and energy is essential for effective combustion, power products, and energy frugality. A well-designed cylinder head ensures optimal tailwind and energy delivery, contributing to the machine’s overall performance, responsiveness, and effectiveness.

Advancements in Cylinder Head Technology

As automotive technology has advanced, cylinder heads have evolved to ameliorate machine performance and reduce emigration. Ultramodern machines frequently feature variable stopcock timing( VVT), which adjusts the timing of the input and exhaust stopcock openings grounded on factors similar to machine speed and cargo. This enhances energy effectiveness, reduces emigration, and improves power affairs. Some advanced machines also integrate turbochargers or intercoolers into the cylinder head to boost performance further. These inventions have made cylinder heads more effective, helping to meet stricter immigration norms while maximizing machine performance.

Precision Manufacturing and Engineering

The design and manufacturing of cylinder heads bear precise engineering. Machine controversy must ensure that cylinder heads are fabricated to exact specifications to help with issues like poor machine performance or element failure. Cylinder heads are made from accouterments like aluminum blends or cast iron due to their capability to repel high temperatures and stresses. Advances in casting ways and accouterments have led to stronger, more featherlight cylinder heads. Precision engineering is essential in maintaining the cylinder head fits rightly, as indeed small diversions can negatively affect machine performance or beget failures.

Common Issues and Cylinder Head Failure

Cylinder head failure is a serious concern that can lead to significant machine damage. Common causes of cylinder head failure include overheating, manufacturing blights, and lack of conservation. The symptoms of a failing cylinder head are usually machine misfires, loss of contraction, mixing of coolant with machine oil painting, and visible cracks. Overheating is often the most common cause of cylinder head failure, which is why it’s important to keep the cooling system healthy.Regular checks of the machine’s cooling system and prompt relief of worn corridors can help avoid precious repairs and help total machine failure.

Conservation and Prevention of Cylinder Head Problems

To avoid cylinder head problems, regular conservation is pivotal. Monitoring the machine’s cooling system, ensuring the oil painting is changed on time, and using quality machine factors can help unseasonable wear and tear and damage. Regular inspections for leaks or cracks in the cylinder head can detect problems at an early stage so that the repairs may be done before further damage occurs. and monitoring a machine’s performance as well (like a power loss or misfires) can alert you to latent cylinder head problems. Insist on precautionary conservation to keep the cylinder head operating in perfect condition and even prolong the action of the machine.

Conclusion

The cylinder head is a key component that heavily influences the efficiency, performance, and longevity of an engine. Its function is to control the input and exhaust gases, the air-energy admixture and to maintain the cooling system incorporating m of the machine.As machine technology advances, cylinder heads have become more effective, inventions like variable stopcock timing and turbocharging.

Read more : How to Avoid Common Mistakes in ECU Remapping